SpaltFix K-700 Vario | 710 a-Vario Saw splitter: Stationary & (fully) automatic

- Efficient 70 cm Log ∅ max.

- Powerful 19 t Splitting power max.

- Fast 27 m3 cubic meters per hour

At the INTERFORST 2022 we presented you our latest additions to the VARIO saw splitter family: the SpaltFix K-700 & the SpaltFix K-710 a-Vario. Both process logs with a diameter of up to 70 cm. Also new is the IIoT-Anbindung (Industrial Internet of Things) of the splitter, as well as the fully automatic feeding system “AutoFeed”.

IIoT allows for system data to be saved in a cloud solution from where they can be retrieved at any time. This allows us to advise you even better and perform software updates for you.

Karlheinz Brodschneider, Development

- Successor to the SpaltFix K-650

- IIoT connection

- IIOT connection

- An “AutoFeed” feeding system is available for even more convenience

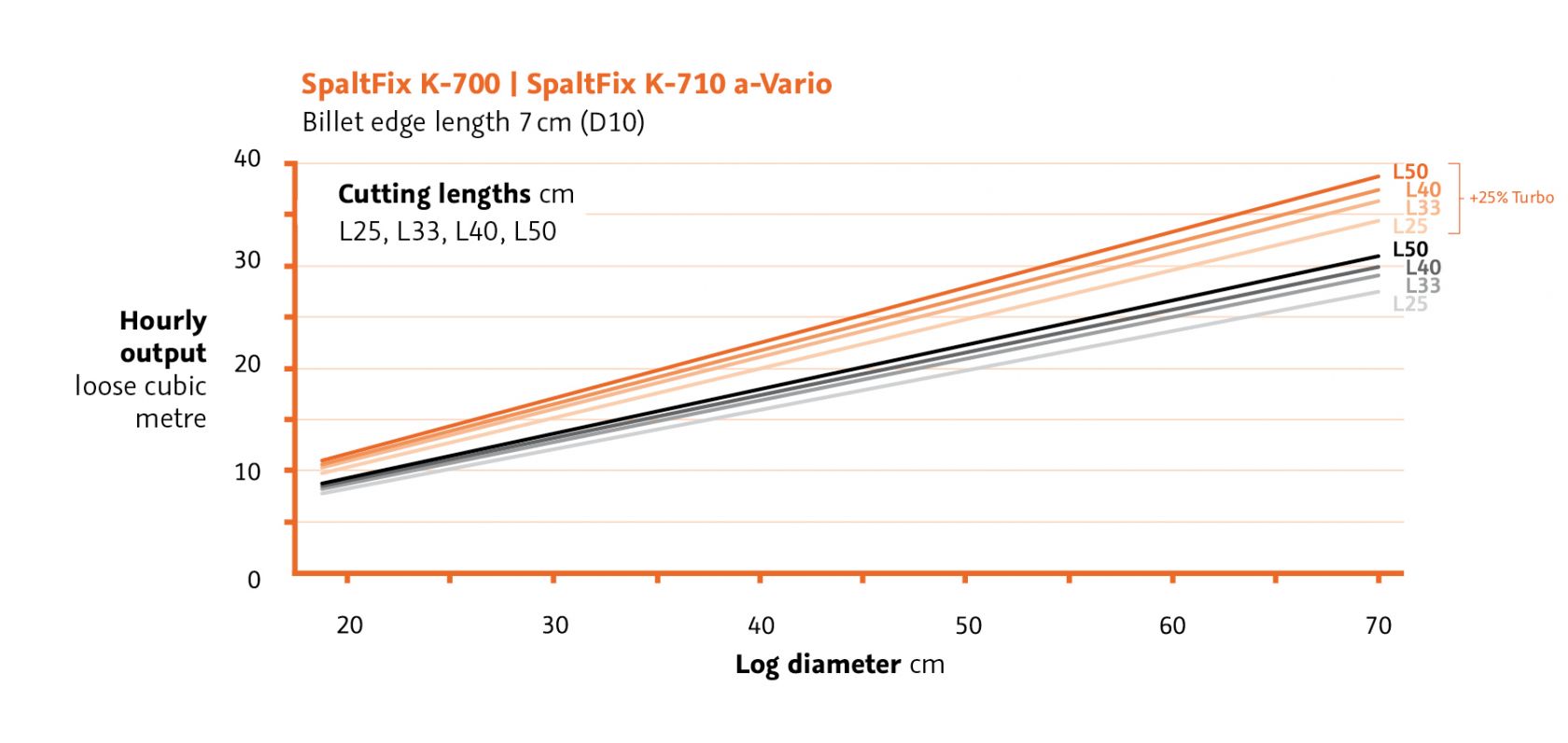

The new Turbo version of the “AutoSplit” provides 25 % more performance. This allows you to work even more efficiently and make higher profits!

- OUT NOW: der AutoFeed für den SpaltFix K-710 a-Vario by POSCH Leibnitz

- POSCH K-710 a-Vario ⚡Turbo⚡ Firewood Factory, A.H. Hardwood Logs - Jas P Wilson Customer case study

Posch Gesellschaft m.b.H.

in 8430 Leibnitz, worldwide