LogFix – separates billets from splinters in next to no time

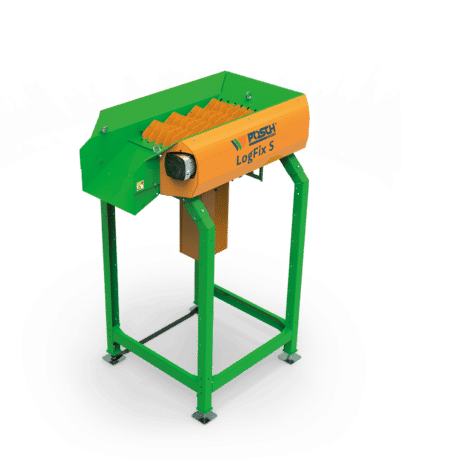

LogFix S – the compact solution

We developed this compact solution especially for the cleaning of logs processed with automatic firewood processors with a splitting knife for max. 8 parts. For loading, conveyor belts with a max. width of 65 cm are used as well.

- Screen width 3.8 cm

- Screen surface 85 x 50 cm (lxw)

- 4 rotating rollers

- Cleaning throughput max. 20 loose m³/h

LogFix L – versatile log screen

The LogFix L was designed for medium volumes of wood processed with the POSCH SpaltFix models or a firewood processor. The seven rotating rollers rotate with 50 rotations per minute and make very little noise.

- Screen width 3.8 cm, optionally adjustable 3-4.5 cm

- Screen surface with 10° upward gradient, 150 x 75 cm (lxw)

- 7 rotating rollers

- Roller speed 50 rpm

- Cleaning throughput max. 25 loose m³/h

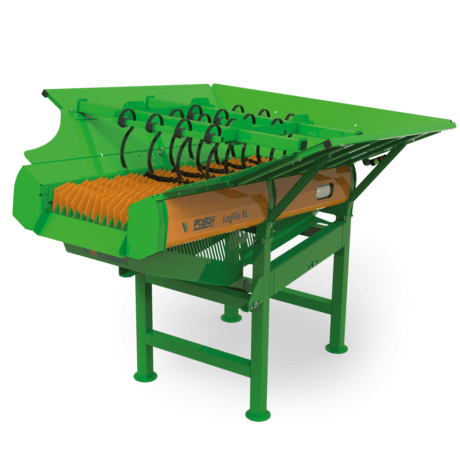

LogFix XL – powerful log screen for large volumes of wood

The extra-large LogFix XL cleans large volumes of wood processed with a POSCH SpaltFix model. The LogFix XL is also an excellent option for the processing of firewood after artificial drying. A hopper which serves as a buffer for charging by means of a front loader is optionally available. 15 rotating rollers separate the undesirable chips, bark pieces and splinters from the firewood and drop them. They work slowly and quietly. With the radio remote control, the screen can easily be switched on and off from any operator position. Comb teeth are optionally available.

- Screen width 4.5 cm, optionally adjustable 3-4.5 cm

- Screen surface 10° upward gradient, 350 x 100 cm (lxw)

- 15 rotating rollers

- Roller speed 93 rpm

- Cleaning throughput max. 60 loose m³/h