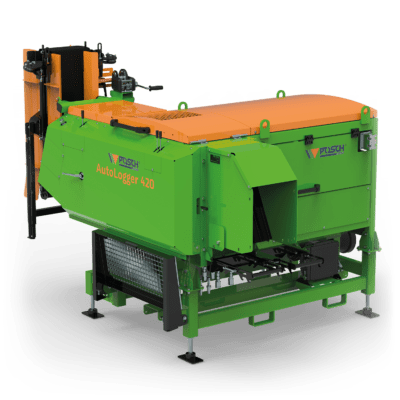

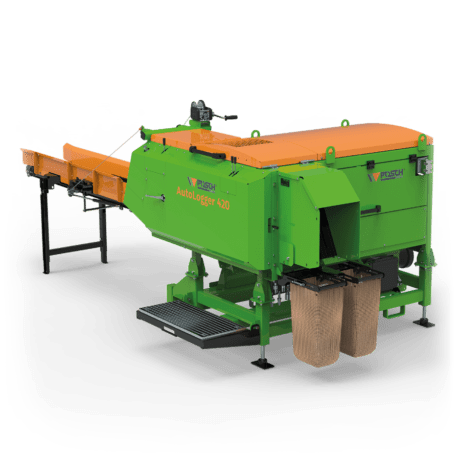

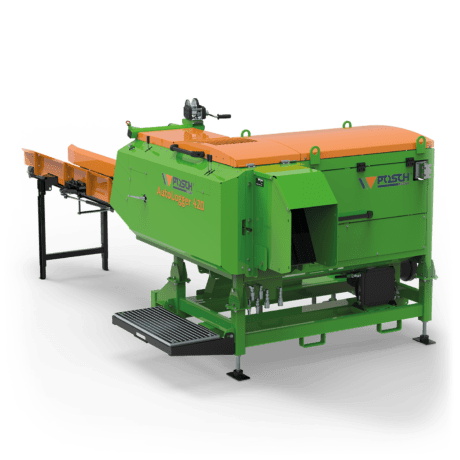

Automatic firewood machine AutoLogger 420

Misshapen or oversized wood? Make it profitable!

Processes wood of poor initial quality

How does the AutoLogger work?

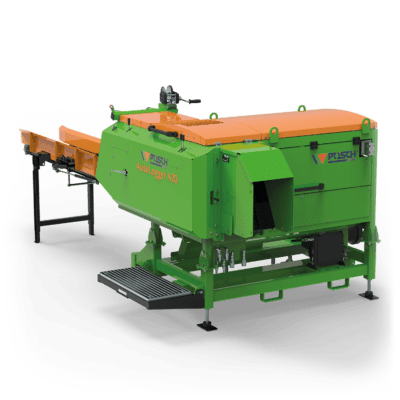

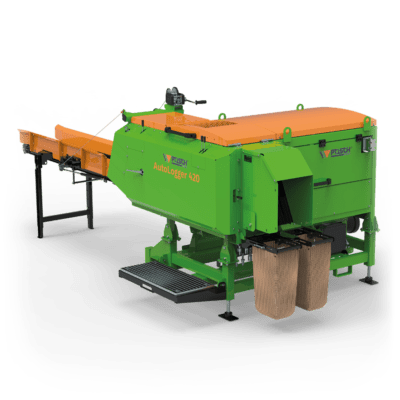

- Loading is simply done via the buffer conveyor.

- An X-shaped splitting knife automatically transforms the trunk sections into firewood or kindling

- A conveyor belt either transports the logs away or

- the firewood is packed directly into net bags.

The key data

- For logs of 10-41 cm diameter

- Log length 12-33 cm

- Variable length of the log edge (from 3 to 10 cm length)

- Up to 25 logs per operation, depending on edge length

- 12 tons splitting force

- Height-adjustable feet

- Operator platform

- Buffer conveyor can be folded up via manual rope winch

- Fork-lift support

Which wood is suitable for the splitting machine?

- Wood of poor quality which is not suitable for conventional purposes

- Wood that needs to be prepared with a chainsaw (interesting for arborists), e.g. arb waste

- Half logs: e.g you could split down an 80 cm log in half on a HydroCombi and then put it through the AutoLogger

- Timber or tree trunk sections, timber offcuts

- Wind-blown trees