The POSCH history

1947

In the washhouse of his parents-in law's home in Leibnitz, Ferdinand Posch, a trained metal worker, established a small metalworking shop and carried out minor turning and cutting work for the first time. The Posch rope winch of 1952 became the first series-produced device and was in great demand. He developed the prototype of a maize husking machine which was later successfully produced in series as "Schälboy", it remained a firm part of the product line for 30 years.

1967

Heinz-Peter Posch took over his father's company. In 1968, he developed the "Maisrebler P1500" with an hourly output of 1500 kg. In 1970, it was followed by the artificial fertiliser row spreader "Streufix", a fertiliser in the form of a pushcart for two rows for maize cultivation.

1972

With the first mechanical wood splitter "Maxi", POSCH started its product lines for firewood processing. It remained part of the product line until 1999. In 1974, the first storehouse with 1,000 m² was built on the grounds of today's company headquarters.

1978

Establishment of Posch GmbH. Relocation of complete production to Kaindorf. The first POSCH logo was created. In 1979, the development and production of circular saws was started there, for example of roller-bench saws, tilting table saws and tilting saws with a variety of drives.

1980

The first hydraulic wood splitters were developed "HydroMax 10t". The first computer-controlled HEID turning machine for the series production of the Maxi Kegel was purchased. In 1981, "Hydro-Mini" with 8t and "HydroSuper" with 20t splitting power were next.

1983

The "Sägomat 500" and the "Spaltboy" were introduced to the market. The "Scheitermat" and the "Spaltfix 300" were developed. So the cutting, splitting and loading of firewood in one work step became possible. POSCH put the first NC nibbling machine for punching out sheet metal parts in operation.

1985

The first "HydroCombi" with 20t splitting power and splitting stroke 1 m and the "SpaltAxt" 6t/8t conquered the market. In 1986, the new office building for sale and development with adjacent testing department was built and the production space was extended. The "SpaltAxt 8t" was made available with adjustable splitting table for metre-long logs for the first time.

1986

With the brand registration of POSCH-Leibnitz as "specialist for firewood making", the quality offensive was started as well. In 1987, the first ASEA welding robot with tilting table was used. A year later, it was followed by a second one. In 1989, the dip painting plant with pre-treatment and two possible top coats in the POSCH colours green and orange was put in operation. The first laser cutting plant followed in 1990.

1992

Development of the current Posch logo and registration as word mark and picture mark. The new slogan was: Cutting. Splitting. Chopping. Technology for our environment. In 1992, the Bavarian distribution agency in Velden/Vils was established. In 1993, the new assembly hall with about 3,000 m² was built in Kaindorf. Posch conquers the continent. In 1995, POSCH was certified according to the quality management system ISO 9001.

1998

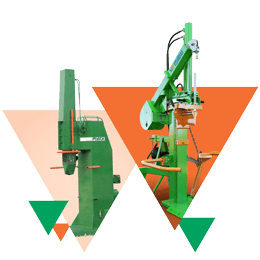

Award of the national coat of arms. Order of merit for special services rendered to the Austrian economy. And POSCH kept making progress. In 1999, there was the market introduction of the HOME range with machines for private households. At the same time, POSCH also extended its special and industrial machinery range with the "Spaltfix SPK-500" in 2000, large machines such as the "SplitMaster Crane" followed.

2003

After the largest production hall with 5,300 m² was put in operation, Heinz-Peter Posch went into his well-deserved retirement. He made the company number 1 in Europe in the field of firewood processing over the past decades. In 2004, his daughter Petra Tinnacher and his son-in-law Ing. Johann Tinnacher took over the management. Elfriede Posch continued to manage all marketing activities until the end of 2006. She established the brand POSCH from its beginnings and made it into what it is today.

2011

The Fixomatic system for more safety and user-friendliness for firewood splitting and the new tilting saw "Wipp-Säge GS" were developed. As a result, we were the first and only manufacturer to receive the GS-certificate.

2013

The new production hall with 4,000 m² and the start-up of the powder coating facility in 2013 rang in a new era of premium quality, reliability and value stability.

2015

A product campaign worth seeing was introduced with a new presence. The new catalogue and the new website present a number of improved or new products. The new "HydroCombi 18" with the new rope winch is the best HydroCombi ever. The "SpaltFix K-650 Vario" cuts whole logs with a diameter of up to 65 cm into fine billets and so makes firewood processing more profitable than ever. The new "AutoCut" also surpasses everything known to date as far as automatic saws are concerned.

2017

The SpaltFix K-Vario principle enabled POSCH to achieve the desired quality improvement for firewood processing. The machine, powerful and efficient, produces billets with the required edge length from logs up to 65 cm. The highest configuration level is now also available for mobile applications.

Upload your POSCH moment and be part of the story!

Simply snap a photo & upload!